Semiconductor Manufacturer Unveils Latest Breakthrough in Tiny Copper Wires

By:Admin

Introduction:

In today's rapidly evolving technological landscape, companies are constantly seeking new ways to enhance their products. In line with this, [{Company Name}], a leading manufacturer in the field of advanced materials, has developed a groundbreaking product called Micron Cu. This innovative copper material promises to revolutionize industrial applications across various sectors, offering superior performance and unprecedented versatility.

[Company Name] has a long-standing reputation for its commitment to research and development, constantly striving to provide cutting-edge solutions to meet the evolving needs of its clientele. With the introduction of Micron Cu, the company aims to further solidify its position as an industry leader. Let us delve deeper into the features and potential applications of this game-changing copper material.

Unleashing the Power of Micron Cu:

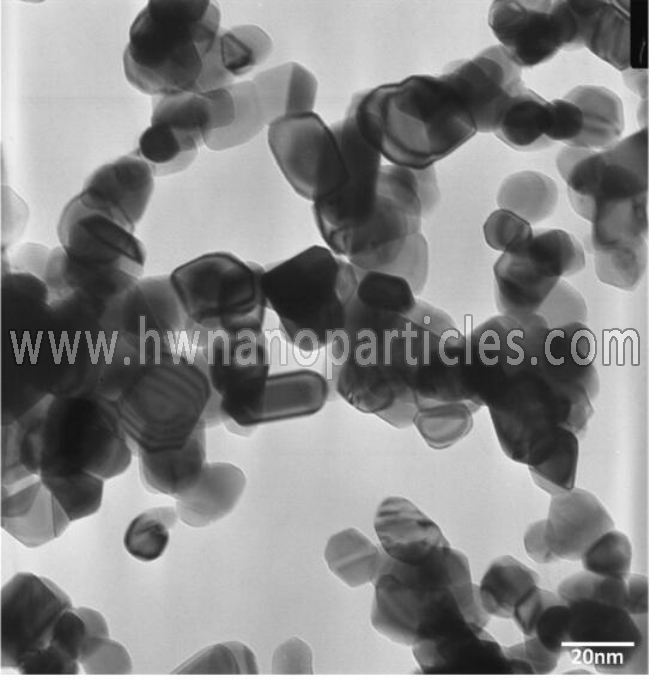

Micron Cu is a high-purity, micron-sized copper powder that pushes the boundaries of traditional copper materials. Its unique composition, developed through advanced proprietary processes, enables superior mechanical properties, electrical conductivity, and thermal management capabilities. With its smaller particle size, Micron Cu exhibits enhanced dispersion and homogeneity compared to conventional copper products, resulting in superior bonding and composite formation.

The applications of Micron Cu span across several industries, including electronics, automotive, aerospace, and renewable energy. In the electronics sector, this next-generation copper material serves as an excellent catalyst for advanced printed circuit boards (PCBs), delivering unparalleled electrical conductivity to meet the demanding requirements of modern devices.

In the automotive industry, Micron Cu finds applications in the manufacture of automotive heat exchangers, where its exceptional thermal management properties ensure efficient heat dissipation. Additionally, its high strength and conductivity make it a preferred choice for various connectors and terminals, improving overall vehicle performance.

The aerospace sector can benefit from Micron Cu's lightweight yet robust nature. The material's exceptional conductivity, combined with its resistance to corrosion, offers enhanced performance and durability for critical components such as heat sinks, antennas, and electrical connectors. Furthermore, its remarkable thermal capabilities make it ideal for use in satellite systems, where temperature control is of utmost importance.

Renewable energy systems, such as solar panels and wind turbines, rely on efficient energy transfer and conduction. Micron Cu's exceptional electrical conductivity makes it an ideal component in these applications, ensuring precise energy management and optimal performance.

A Sustainable Solution:

Aside from its outstanding performance, Micron Cu aligns with [{Company Name}]'s commitment to environmental sustainability. The copper material is sourced responsibly, adhering to the highest ethical and environmental standards. Additionally, Micron Cu's compatibility with existing manufacturing processes facilitates a seamless integration without generating additional waste or requiring significant infrastructure changes.

Conclusion:

With the introduction of Micron Cu, [{Company Name}] is revolutionizing the industrial landscape by providing an innovative copper material that surpasses traditional alternatives. Its remarkable properties empower industries to achieve new heights of performance, efficiency, and sustainability.

[{Company Name}]'s continued dedication to research and development highlights its commitment to pushing the boundaries of advanced materials. As industries continue to evolve, Micron Cu stands poised to shape the future, unlocking unprecedented possibilities in various sectors and driving innovation to new heights.

Company News & Blog

Revolutionary Nano Iron Technology Discovered for Water Treatment

Title: Cutting-Edge Nano Iron Technology Revolutionizes Industrial ProcessesIntroduction:In recent years, scientific advancements have propelled various industries towards innovative solutions aimed at achieving cleaner and more sustainable practices. One such breakthrough is the development of nano iron technology, poised to revolutionize industrial processes across multiple sectors. By harnessing the unique properties of nano iron particles, scientists at [Company Name] have created a novel approach to address environmental challenges and enhance operational efficiency. This article explores the potential applications of nano iron and the pioneering efforts of [Company Name] to integrate this game-changing technology.1. Understanding Nano Iron:Nano iron comprises tiny iron particles at the nanoscale level, typically ranging from 1 to 100 nanometers in size. These particles possess distinctive physicochemical properties, such as high reactivity, large surface area, and excellent dispersibility. These characteristics enable nano iron to exhibit enhanced catalytic behavior, making it an exceptional candidate for various industrial processes.2. Environmental Remediation:The implementation of nano iron technology has brought unprecedented benefits to environmental remediation efforts. Contaminants like heavy metals, organic pollutants, and waterborne pathogens can be effectively removed or degraded using nano iron-based materials. Unlike traditional remediation methods, which often involve hazardous chemicals or extensive excavations, nano iron provides an eco-friendly and efficient alternative. The particles have the ability to break down or immobilize contaminants, mitigating risks and promoting sustainable management of contaminated sites.3. Water Treatment:With water scarcity becoming an increasingly pressing global issue, nano iron offers a promising solution for water treatment. Its catalytic properties allow for the effective removal of pollutants, including organic dyes, pharmaceutical residues, and pesticides. Additionally, nano iron particles can be utilized in advanced oxidation processes to degrade pollutants and enhance the efficiency of existing water treatment systems. By harnessing this technology, industries and communities can ensure a safe and sustainable water supply.4. Industrial Processes:Aside from environmental applications, nano iron exhibits immense potential to revolutionize diverse industrial processes. The reactivity and high surface area of nano iron particles enable their utilization in catalysts, magnetic materials, energy storage technologies, and more. By incorporating nano iron, industries can enhance efficiency and reduce waste, ultimately contributing to the development of a more sustainable economy.5. Pioneering Efforts of [Company Name]:[Company Name], a leading innovator in the field of nanotechnology, has been at the forefront of harnessing nano iron's potential across various sectors. Through extensive research and development, they have successfully developed cutting-edge nano iron-based materials that are both cost-effective and environmentally friendly. By collaborating with industries and academia, [Company Name] aims to accelerate the adoption of nano iron technology on a global scale.Conclusion:Nano iron technology is revolutionizing industrial processes by providing innovative solutions to environmental challenges, water treatment, and enhanced productivity. [Company Name]'s pioneering efforts in developing and commercializing nano iron-based materials are driving the widespread adoption of this groundbreaking technology. As industries increasingly prioritize sustainability, nano iron is poised to play a pivotal role in shaping a cleaner and more efficient future.

Mysterious white powder found in parcel sent to Australian consulate

Title: Groundbreaking Powder Discovered to Revolutionize Multiple IndustriesIntroduction:In an exciting scientific breakthrough, researchers have developed a remarkable powder with immense potential to transform various industries. This revolutionary invention, known as BN powder, has captured the world's attention with its exceptional properties and the numerous applications it offers. From electronic devices to energy storage, this cutting-edge substance presents unprecedented opportunities for innovation and advancement. Let us dive deeper into this groundbreaking discovery and explore its transformative potential.Paragraph 1: Discovering BN PowderBN powder, short for Boron Nitride powder, is a unique material that possesses a myriad of extraordinary qualities. Developed after years of extensive research, this technologically advanced substance demonstrates superior thermal conductivity, electrical insulation, and mechanical strength. These remarkable characteristics make it an ideal candidate for a wide range of applications that push the boundaries of conventional materials science.Paragraph 2: Unleashing the Power of BN PowderThe field of electronics is set to witness a major revolution with the incorporation of BN powder into electronic devices. Due to its excellent thermal conductivity properties, BN powder can efficiently dissipate heat, making it a game-changer in manufacturing components for modern gadgets such as smartphones and laptops. This breakthrough powder can help prevent overheating issues that often plague electronic devices, thereby enhancing their performance and longevity.Paragraph 3: BN Powder in Energy StorageThe energy storage sector could greatly benefit from the integration of BN powder in the development of advanced batteries. Its high electrical insulation properties make BN powder an ideal component for creating high-performance separators, which are critical for ensuring the safety and efficiency of batteries. This innovation could potentially revolutionize the renewable energy industry, offering enhanced storage solutions for solar and wind power systems.Paragraph 4: Automotive ApplicationsWith the global shift towards cleaner transportation, BN powder can play a significant role in revolutionizing the automotive industry. Its exceptional thermal conductivity allows for efficient heat dissipation in electric vehicle (EV) batteries, preventing potential safety hazards. Additionally, the mechanical strength of BN powder makes it an excellent candidate for lightweighting vehicles, improving fuel efficiency and reducing carbon emissions.Paragraph 5: Medical and Aerospace ApplicationsBN powder's outstanding properties extend beyond electronics and energy storage. In the medical field, it can be utilized in various applications, including dental equipment and implants, thanks to its biocompatibility and thermal insulation. Similarly, the aerospace industry stands to gain from BN powder, as its high thermal stability and low weight make it an ideal material for insulating spacecraft and ensuring their durability under extreme conditions.Paragraph 6: Environmental Implications and Future ProspectsThe environmentally friendly nature of BN powder is yet another reason to celebrate this breakthrough. With its potential to improve energy storage systems and enhance efficiency in various industries, BN powder plays a pivotal role in sustainable development. As research and development efforts continue, it is expected that BN powder will find even more applications in diverse fields, leading to further advancements and a cleaner, greener future.Conclusion:The emergence of BN powder heralds a new era in materials science, offering unparalleled possibilities for innovation across multiple industries. Its exceptional properties make it a sought-after material for electronics, energy storage, automotive, medical, and aerospace applications. As scientists and engineers continue to explore and harness the potential of BN powder, we can anticipate a future where technological advancements are unbound by traditional material limitations. This discovery paves the way for a brighter and more sustainable world.

New Submicron TiC Powder Released for Enhanced Material Performance

Submicron TiC Powder: Revolutionizing the World of Materials ScienceIn recent years, groundbreaking advancements in materials science have paved the way for innovative technologies that have transformed various industries. Among these revolutionary breakthroughs is the development of submicron Titanium Carbide (TiC) powder. This cutting-edge material has garnered immense attention, with its unique properties and versatile applications capturing the interest of researchers, engineers, and industry leaders worldwide.Submicron TiC powder, as the name suggests, consists of particles with sizes smaller than one micrometer. This remarkable powder is produced using advanced manufacturing techniques, which finely disintegrate the raw materials to create particles with an exceptional level of purity and uniformity. While conventional TiC powders are widely used, it is the submicron variant that has become the golden standard in advanced material engineering due to its superior properties and enhanced functionality.One of the key advantages of submicron TiC powder lies in its remarkable hardness. With a hardness rating close to that of diamond, TiC powder is considered one of the hardest known materials on Earth. This exceptional hardness makes it ideal for applications that demand extreme durability, such as cutting tools, wear-resistant coatings, and high-performance refractory materials. Its hardness ensures prolonged lifespan and superior performance in high-stress environments, revolutionizing the durability and reliability of numerous industrial applications.Additionally, submicron TiC powder exhibits excellent thermal stability and resistance to oxidation. This makes it an invaluable component in the production of high-temperature materials, including ceramic composites and heat-resistant coatings. The thermal stability of TiC powder enables it to withstand extreme temperatures without significant degradation, thereby enhancing the longevity and performance of crucial components in various industries like aerospace, electronics, and energy production.Moreover, the small particle size of submicron TiC powder contributes to its exceptional mechanical properties. The fine particles allow for a higher surface area, leading to improved reactivity and sintering ability. This makes it an ideal reinforcement material for metal matrix composites, producing lightweight yet strong materials with enhanced mechanical strength and wear resistance. By incorporating submicron TiC powder into these composites, manufacturers can produce components that are not only lighter but also offer greater structural integrity and improved performance.To leverage the vast potential of submicron TiC powder, companies worldwide are now adopting it as a critical component in their product development and manufacturing processes. Among the industry leaders in the production and supply of submicron TiC powder, one company stands out for its commitment to innovation and excellence.**Company Introduction: [Brand Name]**[Brand Name] is a global leader in the production of submicron TiC powder. With a rich history spanning several decades, the company has earned a stellar reputation for its unwavering dedication to quality, cutting-edge research, and customer satisfaction. Operating at the forefront of materials science, [Brand Name] has harnessed the true potential of submicron TiC powder and is continuously pushing the boundaries of its applications.In their state-of-the-art manufacturing facilities, [Brand Name] uses an advanced manufacturing process that ensures the production of submicron TiC powder with unparalleled purity and consistency. The company combines extensive expertise, stringent quality control measures, and adherence to international standards to deliver products that exceed customer expectations.Recognizing the diverse needs of their clientele, [Brand Name] offers a broad range of submicron TiC powder grades, tailored to suit specific applications across industries. Their skilled team of researchers and engineers work closely with customers, providing technical support and customized solutions to meet unique requirements. With an unwavering commitment to innovation, [Brand Name] endeavors to continuously develop new and improved grades of submicron TiC powder that unlock possibilities in various cutting-edge technologies.As the demand for high-performance materials grows across industries, the significance of submicron TiC powder continues to rise. Collaborating with [Brand Name] ensures access to the finest quality submicron TiC powder, enabling companies to develop advanced products, enhance their competitive edge, and drive success.In conclusion, submicron TiC powder represents a remarkable advancement in materials science, offering exceptional hardness, thermal stability, and excellent mechanical properties. Its applications are wide-ranging, with significant implications for industries such as aerospace, electronics, and energy production. As a global leader in the production and supply of submicron TiC powder, [Brand Name] stands at the forefront of innovation, supporting companies in unlocking the immense potential of this extraordinary material.

Latest Updates on Nano Zinc Prices: Price Analysis and Market Trends

Title: Surge in Nano Zinc Prices as Demand GrowsIntroduction:In recent years, the demand for nano zinc has witnessed a significant surge, leading to a sharp increase in its market price. Nano zinc, a highly sought-after material, finds extensive applications in sectors like electronics, medicine, cosmetics, and energy, owing to its unique properties and benefits. This article delves into the current market trends for nano zinc and its potential impact on various industries.Market Analysis:Nano zinc (Zn), with its particle size ranging from 1 to 100 nanometers, has gained immense popularity due to its enhanced chemical reactivity, large surface area, and unique catalytic properties. These characteristics make it a versatile component across various industries.The global nano zinc market has experienced substantial growth over the past few years and is projected to continue expanding. This growth can be attributed to the rising demand for eco-friendly products, increasing investments in research and development, and the growing adoption of nanotechnology. Furthermore, the demand for nano zinc is boosted by its application in sunscreen lotions, anti-bacterial coatings, electronic devices, and advanced batteries, to name a few.Factors Driving Nano Zinc Prices:Several factors contribute to the current surge in nano zinc prices. Firstly, the limited availability of raw materials required for nanoparticle production, such as high-grade zinc ore, has impacted the supply chain. Additionally, the energy-intensive process of producing nano zinc nanoparticles adversely affects the overall production capacity. These supply-related constraints have led to an imbalance between demand and supply, ultimately resulting in price increases.Furthermore, the increasing research and development activities involving nano zinc also impact market prices. As more industries and scientists explore the potential of nano zinc, there is a mounting demand for this material. The continuous innovations and discoveries in nanotechnology applications further accentuate the demand-driven price upswing.Effects on Industries:1. Electronics: Nano zinc plays a crucial role in the electronics sector, particularly in the production of batteries, conductive films, and supercapacitors. The rising prices of nano zinc may impact the production costs of electronic devices, potentially leading to increased prices for consumers.2. Medicine: Nano zinc finds significant applications in medical treatments, including drug delivery systems, imaging agents, and antimicrobial coatings. The surge in prices might challenge the feasibility and accessibility of these advancements. However, the medicinal benefits offered by nano zinc open avenues for research and development investment, leading to potential breakthroughs in healthcare.3. Cosmetics: Nano zinc is extensively used in the production of sunscreens and skincare products due to its ability to provide efficient UV protection and its antibacterial properties. As prices rise, cosmetic companies may face difficulties in maintaining competitive pricing, leading to possible increases in product costs.4. Energy: Nano zinc is an integral component in advanced batteries and solar panels, contributing to enhanced energy storage and conversion. The price escalation may impact the adoption of renewable energy technologies, hindering the global transition towards sustainability. However, continuous research may lead to alternative materials or manufacturing techniques, mitigating this potential setback.Conclusion:The surging prices of nano zinc have caught the attention of various industries relying on this material for their products and advancements. Despite the challenges posed by the price increase, the unique properties and widespread application prospects of nano zinc continue to attract investments and innovations. Efforts to improve production efficiency, explore alternative raw material sources, and expand applications may alleviate pricing concerns and foster sustainable growth in the nano zinc market.

Nanoparticles of Vanadium Dioxide Show Promise for Improved Data Storage and Processing

Vanadium Dioxide Nanoparticles Disrupt Traditional Heating and Cooling MethodsA company has recently released a groundbreaking new product that could change the way we heat and cool our homes and buildings. The product in question is a type of vanadium dioxide nanoparticles that are capable of disrupting traditional heating and cooling methods. The product is a cutting-edge technology that has been researched for years and has been released by a well-known manufacturer of nanoparticles. This new technology has been named as the ‘revolution in energy technology’ due to its exceptional energy-efficient qualities. The product uses a unique mechanism that allows it to absorb and release heat depending on the environment, creating a perfect blend of temperature management. The nanoparticles are said to possess an inbuilt energy-saving mechanism that ensures that the energy output is reduced significantly and the environment is maintained at a comfortable temperature.The invention marks a major development in the energy-saving field, where global consumption of electricity is on the rise, and sustainability is at the forefront of public concerns. The vanadium dioxide nanoparticles offer a solution that is efficient and cost-effective. The technology used in the nanoparticles is said to be different from what traditional HVAC units use. The nanoparticles react to the environment and the incoming infrared radiation to regulate the temperature, effectively reducing energy consumption. Unlike traditional HVAC systems, where air conditioners consume large amounts of energy, the nanoparticles are a passive technology that needs no electricity to work. This makes it an ideal solution for residential and commercial use, reducing operating costs and increasing the efficiency of the HVAC system.Moreover, the vanadium nanoparticles are designed to work with any building. Whether it’s an old building that requires a new HVAC system or a new building that needs to be energy efficient from the get-go, the nanoparticles can be easily integrated with the existing system. This is an exciting possibility because it means that home and building owners will no longer have to invest in new HVAC systems to benefit from this technology.The revolutionary nanoparticles use a process called phase transition to adjust the temperature. In layman terms, this means that the nanoparticles change the way they behave under certain circumstances. In this case, the nanoparticles change their state from insulator to conductive material when the temperature is at a specific point. This process allows the nanoparticles to absorb infrared heat radiation and control the temperature more efficiently. The company behind this invention is known for its high-quality nanotechnologies, which are used in various applications worldwide. The company's CEO was ecstatic regarding the launch of this new product. He stated that: "We are pleased to launch such an innovative product that has the potential to revolutionize the HVAC industry and make energy-efficient buildings accessible to everyone. The vanadium dioxide nanoparticles are a game-changer, and we are thrilled to be the first to bring it to the market."In conclusion, the vanadium dioxide nanoparticles are a cost-effective and efficient solution that could eradicate the need for traditional HVAC systems. The nanoparticles are designed to work with any building and offer a sustainable and energy-efficient alternative. The release of this product is an exciting development in the HVAC industry and could have a significant impact on the way we heat and cool buildings in the future.

Groundbreaking Submicron TiC Powder: Unveiling the Future of Advanced Materials

Submicron TiC Powder Launches New Era of High-Performance Materials Submicron TiC powder has been developed by an innovative materials company, changing the game when it comes to high-performance materials. With an excellent combination of high strength and high toughness, this new material is ideal for a wide range of applications. From automotive and aerospace to medical and defense, submicron TiC powder is set to revolutionize many industries.The new submicron TiC powder is a result of several years of research and development by the company’s team of material experts. The powder is designed to have a particle size distribution of less than one micron, making it one of the highest performing materials on the market. The powder is created using a patented process which ensures that the product is of a consistent quality and purity, without any impurities that could affect its performance.The submicron TiC powder has a high surface area and excellent sinterability, which makes it easy to produce dense parts with superior mechanical properties. It has been tested to show an excellent combination of high strength and high toughness, making it ideal for applications where materials need to be strong, yet also flexible. The material is particularly useful in manufacturing cutting tools such as drills and saws, where the combination of strength and toughness is essential.The company has invested in state-of-the-art manufacturing facilities to produce and supply the submicron TiC powder in large quantities. According to the company’s CEO, the launch of the new material is a significant milestone in the company’s history. He said, “We are proud to be at the forefront of developing new materials that will drive innovation in a variety of industries. The submicron TiC powder is a testament to our commitment to excellence and innovation, and we are excited to see the impact it will have on the industry.”The launch of the submicron TiC powder comes at a time when the demand for high-performance materials is increasing in various sectors. For instance, the aerospace industry is continually looking for materials that are lightweight, high-strength, and heat-resistant. In the medical field, the demand for implants with excellent mechanical properties is on the rise. The submicron TiC powder fulfills all these requirements and more.Several major companies have already expressed an interest in incorporating the submicron TiC powder into their production line. The automotive industry is also one of the sectors that will benefit from this new material. The trend towards electric vehicles has created a demand for lightweight and durable materials, and the submicron TiC powder could be the solution to this challenge.The submicron TiC powder production process is environmentally friendly, as it produces less waste than other conventional methods. The company uses advanced technology to ensure that the production process is sustainable, with minimal impact on the environment.In conclusion, the launch of the submicron TiC powder marks a significant milestone in the world of materials science. Its excellent combination of high strength and high toughness makes it ideal for a wide range of applications across many different industries. The material’s outstanding performance, combined with its eco-friendly production process, sets a new standard for high-performance materials. The company is excited to see the impact this new material will have on various industries and is set to deliver a game-changing product that will revolutionize the industry.

Vanadium Dioxide Prices Skyrocket as Demand Surges for Smart Glass and Sensors

Title: Global Vanadium Dioxide Price Fluctuations Forecasted to Impact Market DynamicsIntroduction (81 words):The market for vanadium dioxide, a key component in various industries, is expected to witness significant fluctuations in the coming months. Vanadium dioxide is widely used in the automotive, electronics, energy storage, and construction sectors. In recent years, the pricing of vanadium dioxide has become a topic of concern for industry experts and market participants. This article delves into the current vanadium dioxide price trends, explores the factors affecting its pricing, and discusses the potential impact on various market segments and companies operating in this sector.I. Vanadium Dioxide Price Volatility: Factors and Implications (196 words)The cost of vanadium dioxide has experienced considerable volatility over the past few years. Prices skyrocketed in 2017 due to increased demand and supply constraints but retreated in subsequent years as production ramped up. However, the market currently faces a new set of challenges, including global economic uncertainties, supply chain disruptions, and geopolitical tensions, all of which have the potential to impact the vanadium dioxide pricing dynamics.A. Demand-Supply Imbalance and Emerging Market Opportunities (175 words)The demand for vanadium dioxide is driven by several factors. In the automotive sector, its use in smart glass technology is gaining traction. Additionally, the growth of the electronics industry, coupled with increasing energy storage requirements, have further fueled the demand for vanadium dioxide. However, supply side challenges, including restricted availability of vanadium, mining regulations, and the environmental impact of extraction, have resulted in supply shortfalls.B. Geopolitical Factors Contributing to Price Fluctuations (141 words)Furthermore, geopolitical factors, including trade disputes and sanctions, can significantly impact the vanadium dioxide market. As countries strive to secure their critical mineral resources, tariffs, quotas, and other trade barriers can disrupt the global supply chain. Market participants need to keep a close eye on changing diplomatic relationships and trade policies, which may influence the prices and availability of vanadium dioxide.II. Company Spotlight: Leading Vanadium Dioxide Players and Strategies (185 words)Within the market, several key companies dominate the production and supply of vanadium dioxide. These companies invest substantial resources in research and development to introduce innovative and cost-effective production processes. Furthermore, they focus on expanding their global footprint to capitalize on emerging market opportunities and secure a competitive edge.Conclusion (55 words)The vanadium dioxide market is poised for potential disruptions due to various pricing and market dynamics. As demand for vanadium dioxide continues to rise across multiple industries, monitoring price trends, supply chain developments, and geopolitical factors will be paramount. Industry participants should remain vigilant to leverage market opportunities while mitigating potential risks.

Semiconductor Manufacturer Unveils Latest Breakthrough in Tiny Copper Wires

Title: Innovative Micron Copper Sets New Standards in Industrial ApplicationsIntroduction:In today's rapidly evolving technological landscape, companies are constantly seeking new ways to enhance their products. In line with this, [{Company Name}], a leading manufacturer in the field of advanced materials, has developed a groundbreaking product called Micron Cu. This innovative copper material promises to revolutionize industrial applications across various sectors, offering superior performance and unprecedented versatility. [Company Name] has a long-standing reputation for its commitment to research and development, constantly striving to provide cutting-edge solutions to meet the evolving needs of its clientele. With the introduction of Micron Cu, the company aims to further solidify its position as an industry leader. Let us delve deeper into the features and potential applications of this game-changing copper material.Unleashing the Power of Micron Cu:Micron Cu is a high-purity, micron-sized copper powder that pushes the boundaries of traditional copper materials. Its unique composition, developed through advanced proprietary processes, enables superior mechanical properties, electrical conductivity, and thermal management capabilities. With its smaller particle size, Micron Cu exhibits enhanced dispersion and homogeneity compared to conventional copper products, resulting in superior bonding and composite formation.The applications of Micron Cu span across several industries, including electronics, automotive, aerospace, and renewable energy. In the electronics sector, this next-generation copper material serves as an excellent catalyst for advanced printed circuit boards (PCBs), delivering unparalleled electrical conductivity to meet the demanding requirements of modern devices.In the automotive industry, Micron Cu finds applications in the manufacture of automotive heat exchangers, where its exceptional thermal management properties ensure efficient heat dissipation. Additionally, its high strength and conductivity make it a preferred choice for various connectors and terminals, improving overall vehicle performance.The aerospace sector can benefit from Micron Cu's lightweight yet robust nature. The material's exceptional conductivity, combined with its resistance to corrosion, offers enhanced performance and durability for critical components such as heat sinks, antennas, and electrical connectors. Furthermore, its remarkable thermal capabilities make it ideal for use in satellite systems, where temperature control is of utmost importance.Renewable energy systems, such as solar panels and wind turbines, rely on efficient energy transfer and conduction. Micron Cu's exceptional electrical conductivity makes it an ideal component in these applications, ensuring precise energy management and optimal performance.A Sustainable Solution:Aside from its outstanding performance, Micron Cu aligns with [{Company Name}]'s commitment to environmental sustainability. The copper material is sourced responsibly, adhering to the highest ethical and environmental standards. Additionally, Micron Cu's compatibility with existing manufacturing processes facilitates a seamless integration without generating additional waste or requiring significant infrastructure changes.Conclusion:With the introduction of Micron Cu, [{Company Name}] is revolutionizing the industrial landscape by providing an innovative copper material that surpasses traditional alternatives. Its remarkable properties empower industries to achieve new heights of performance, efficiency, and sustainability.[{Company Name}]'s continued dedication to research and development highlights its commitment to pushing the boundaries of advanced materials. As industries continue to evolve, Micron Cu stands poised to shape the future, unlocking unprecedented possibilities in various sectors and driving innovation to new heights.

Discover the Latest Breakthrough in Materials Science: Boron Nitride Creates a Stronger and More Heat-Resistant Alternative to Metals

Title: Revolutionary Breakthrough: Boron Nitride's Endless Possibilities in the World of Advanced MaterialsIntroduction: In today's ever-evolving world, where industries are constantly seeking innovative solutions, the discovery of boron nitride has sparked excitement and revolutionized the field of advanced materials. We proudly present an exclusive insight into the captivating potential and numerous applications of this remarkable compound, paving the way for a multitude of groundbreaking advancements across industries.Unveiling the Power of Boron Nitride:Boron nitride, a compound formed by combining boron and nitrogen atoms, is gaining immense popularity due to its exceptional properties. It possesses a similar structure to carbon, with atoms arranged in hexagonal lattices, leading to unique electrical, thermal, and mechanical characteristics. This compound's ability to withstand incredibly high temperatures, resistance to corrosion, and superior strength make it a versatile material with unlimited potential.Major Company's Role in Boron Nitride Revolution:Leading the forefront of the boron nitride revolution is a renowned company recognized for its exceptional research and development in advanced materials. With years of expertise and groundbreaking innovations, they have successfully unlocked the true potential of boron nitride, revolutionizing multiple industries' capabilities.Endless Applications of Boron Nitride:1. Electronics and Semiconductor Industry:The electronics and semiconductor industry, always in pursuit of higher performance, has found boron nitride to be a game-changer. Its remarkable thermal conductivity, electrical insulation, and low dielectric constant make it an ideal candidate for improving the efficiency and reliability of electronic devices. From high-performance thermal interface materials to electrical insulators, boron nitride has the potential to revolutionize the miniaturization and performance of electronic components.2. Aerospace and Defense Sector:Boron nitride's exceptional thermal and chemical resistance, combined with its high electrical resistivity, is revolutionizing the aerospace and defense sector. Its application as a high-temperature, wear-resistant coating protects critical components and enhances their durability. Additionally, its low radar cross-section properties enable stealth technology advances, ensuring national security.3. Energy Sector:As the world shifts towards renewable energy sources, boron nitride emerges as a significant contributor to this transition. Due to its excellent thermal and electrical properties, it finds potential use in enhancing the performance and efficiency of energy storage systems, such as batteries and fuel cells. By improving heat dissipation and reducing energy losses, boron nitride plays a crucial role in sustainable energy generation and storage.4. Medical and Biotechnology:Boron nitride's biocompatibility, non-toxic nature, and thermal stability open unprecedented possibilities in the medical and biotechnology industries. From drug delivery systems to tissue engineering scaffolds, its versatility enables cutting-edge advancements. Moreover, its high thermal conductivity and resistance to harsh environments make it invaluable for medical instrumentation and diagnostic applications.5. Automotive Industry:Boron nitride's exceptional thermal management properties make it an ideal material for the automotive industry. It can significantly improve the efficiency and longevity of electric vehicle batteries by enhancing heat dissipation and upgrading thermal insulation. Moreover, its lubrication abilities offer potential applications in engine components, reducing friction and boosting overall efficiency.Future Prospects and Developments:With extensive ongoing research and development, boron nitride's potential is yet to be fully explored. As its applications expand across various industries, there is an increasing demand for further advancements, including improved synthesis techniques, cost reduction, and modifications with enhanced properties. Such developments will undoubtedly pave the way for a more sustainable, technologically advanced future.Conclusion:Boron nitride has emerged as a game-changing compound in the world of advanced materials, revolutionizing industries from electronics to aerospace and energy. Its unique thermal, electrical, and mechanical properties have positioned it as a versatile material capable of driving innovative solutions across numerous sectors. With continuous advancements and collaborations, the future of boron nitride appears bright, promising unparalleled technological achievements and a more sustainable tomorrow.

New Study Finds Graphene Oxide GO Powder Holds Promising Potential for Advancements in Various Industries

Recently, a new and exciting innovation has been introduced to the world of science and technology. This is the Graphene Oxide (GO) Powder. This new invention has taken the world by storm and is being viewed as the future of a number of different industries, including medical, aerospace, and electronics. The GO Powder was developed by a leading research and development company, which has been at the forefront of overcoming technical challenges and realizing breakthroughs in nanotechnology products.This company has been dedicated to creating and developing new technologies that are designed to improve people's lives. They have been at the cutting edge of research and development in many different fields, including Material Science, Electronics, Chemical Engineering, and Nanotechnology. The company has a highly trained and experienced team of scientists, engineers, and technicians who are dedicated to developing new technologies that are designed to make people's lives easier, safer, and more efficient.The Graphene Oxide Powder is a cutting-edge innovation that is made from graphene, which is a one-atom-thick sheet of carbon atoms. Graphene is 200 times stronger than steel, making it an incredibly strong and durable material. The GO Powder is created through a process of oxidization, which modifies the properties of graphene, making it more versatile and easier to use.The GO Powder can be used in a variety of different applications, including as an additive for polymer composites, as a conductive ink in printed electronics, as a nanofiber coating for aerospace materials, and can even be used in regenerative medicine and drug delivery systems. The incredible strength and durability of the GO Powder makes it an ideal candidate for use in building materials and construction, as well as a range of other applications.One of the key potential applications of the GO Powder is in the medical field. The Graphene Oxide Powder has been shown to have antimicrobial properties, which make it an ideal candidate for use in the medical industry. For example, the GO Powder can be used to coat medical devices, which would reduce the risk of infection and improve patient outcomes. The GO Powder has also been shown to be effective in treating cancer cells, which could lead to a new wave of cancer treatments that are both effective and safe.Another potential use of the GO Powder is in the aerospace industry. The GO Powder can be used as a lightweight and highly durable coating for aerospace materials, making them more resistant to wear and tear. This could lead to more efficient aircraft, which would have a lower environmental impact and reduce operating costs.In addition, the GO Powder can also be used in the electronics industry. The high conductivity of the GO Powder makes it an ideal candidate for use in electronic devices, such as flexible displays and wearable electronics. This could lead to a new generation of electronic devices that are both durable and flexible.Overall, the introduction of the Graphene Oxide Powder is a game-changer for many different industries. The incredible strength and versatility of the GO Powder make it an ideal candidate for use in a wide range of applications. The development of this new innovation is a testament to the hard work and dedication of the company's team of scientists, engineers, and technicians. The introduction of the GO Powder is a sign of exciting things to come, and we cannot wait to see what the future holds for this groundbreaking innovation.